Systems for the processing and recycling of metals processing and recycling of metals

Engineered Recycling Systems, LLC is a manufacturer of systems that can be used for processing and recycling metals. Our systems shred metal-containing components such as cables and wires and other metallic waste and prepare them for reuse. A recycling system benefits your entire business.

How recycling metals benefit businesses

Especially in these times of climate change, many people are choosing to live a more sustainable and environmentally friendly life and numerous companies, especially in larger industrial sectors, are also working to make all processes more sustainable and climate neutral. Many people associate a sustainable lifestyle with abandonment but do not realize how many benefits it can also bring. The same is true for all industrial companies. Switching to more environmentally friendly processes will require an investment, especially in the beginning, but in the medium, to long term, it can pay off in a variety of ways. In the following, we would like to explain the benefits that our systems for processing and recycling metals have for companies.

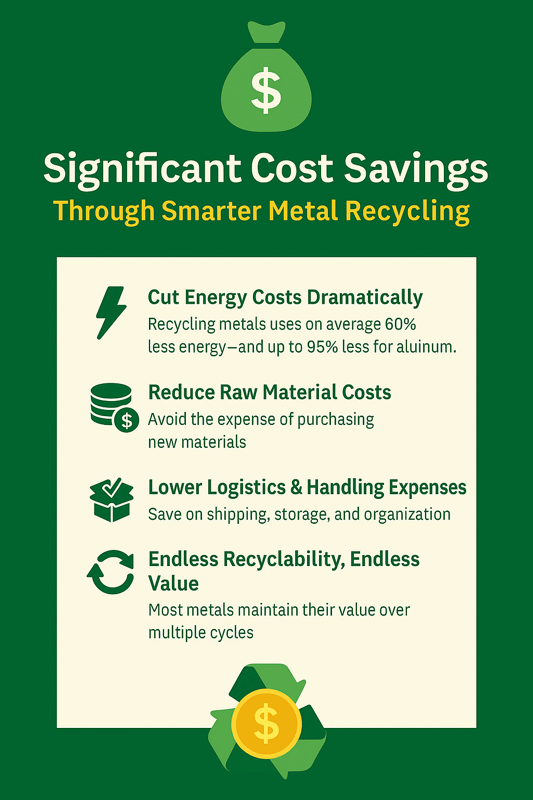

💰 Significant Cost Savings Through Smarter Metal Recycling

Investing in metal recycling isn’t just environmentally smart—it’s a high-impact financial decision that can lead to major savings and long-term business growth.

⚡ Cut Energy Costs Dramatically

Recycling metals consumes far less energy than producing them from raw materials. On average, energy usage is reduced by 60%, and for aluminum, the savings can reach up to 95%. That translates directly into lower operating costs, reduced dependence on volatile energy markets, and faster ROI.

🔄 Reduce Raw Material Costs

By processing and reusing existing metals, your company becomes less reliant on purchasing new materials, which not only lowers supply chain costs but also protects against material shortages and price spikes.

📦 Lower Logistics and Handling Expenses

Handling recycled metals in-house minimizes shipping, storage, and organizational costs—giving your team more control and flexibility.

♻️ Endless Recyclability, Endless Value

Most metals maintain their properties through multiple recycling cycles. Whether reused internally or sold, recycled metals remain a valuable asset—offering resale opportunities and generating an additional revenue stream.

In today’s economy, metal recycling is not just a sustainable choice—it’s a strategic one.

🌍 Recycling Metals Is Good for the Planet — and the Future

Choosing to recycle scrap metal isn’t just smart business—it’s a powerful step toward environmental responsibility.

Instead of ending up in landfills or contributing to pollution, metal scrap can be recovered and reused, reducing the demand for virgin raw materials and minimizing harmful waste. This simple act of recycling helps protect air, water, and ecosystems across the globe.

♻️ Environmental Benefits of Metal Recycling:

-

Up to 500 million tons of CO₂ saved annually through full-scale metal recycling

-

70–80% less air and water pollution compared to raw metal production

-

Massive reductions in energy use and emissions during processing

-

Less mining, drilling, and destruction of habitats—preserving nature for future generations

Mining for new metals is energy-intensive and ecologically damaging. It requires drilling deep into the earth, destroying ecosystems, consuming enormous volumes of water, and releasing greenhouse gases that contribute to climate change.

By choosing metal recycling, you’re making a meaningful contribution to global sustainability—helping reduce emissions, preserve natural resources, and create a cleaner, healthier world for the generations to come.

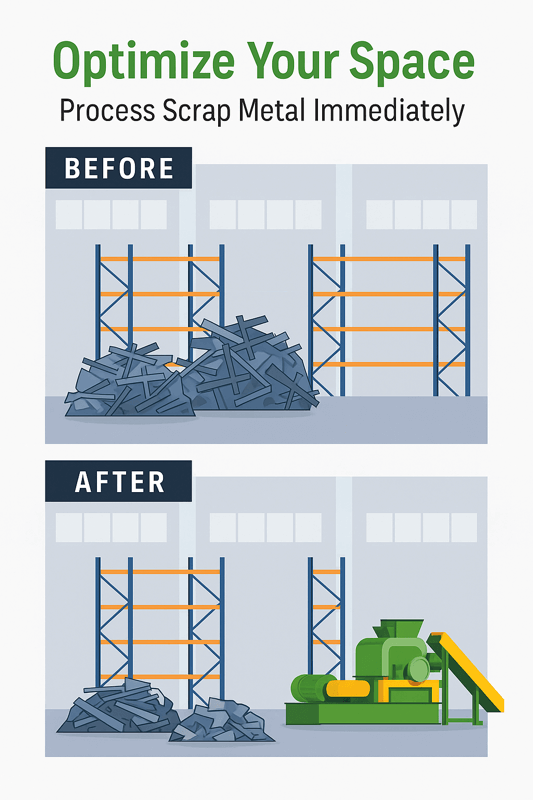

Maximize Operational Space by Processing Scrap Metal On-Site

Accumulating scrap metal for periodic disposal can consume valuable storage space, leading to increased costs and reduced operational efficiency. By implementing on-site scrap metal processing, your company can:

-

Eliminate the need for interim storage, freeing up space for revenue-generating activities.

-

Reduce storage-related expenses, including rent, maintenance, and security.

-

Enhance workflow efficiency by maintaining a clutter-free environment.

According to industry sources, recycling scrap metal not only conserves natural resources but also reduces the demand for landfill space, contributing to environmental sustainability.

By adopting immediate scrap processing, your business can optimize space utilization, lower costs, and support eco-friendly practices.

Our Metal Processing Systems – Turning Scrap Into Strategy

At Engineered Recycling Systems, we do more than build machines—we create end-to-end solutions for one of today’s most pressing industrial challenges: the efficient, clean, and profitable recovery of valuable metals from scrap.

Mountains of tangled wires, mixed materials, and contaminated metal waste are a growing burden for manufacturers and scrap processors alike. Without the right systems in place, that waste clogs up space, drains resources, and leaves behind untapped value.

That’s where ERS comes in.

Our metal recovery and refining systems are custom-engineered to tackle real-world scrap problems—from aluminum-copper radiators and shredded electric motors (“meatballs”) to e-waste PCBs, wire bundles, and ASR. We design systems around your materials, your layout, and your goals—integrating shredding, granulating, separation, and recovery into a single streamlined process.

Whether you’re seeking higher recovery rates, better purity, regulatory compliance, or faster ROI—we help you extract more value and generate less waste.

Let us show you how your scrap can become a strategic advantage.

99% Purity Rate

of metals and plastics.

As copper prices continue to stay strong you need a strong partner. Call us today for a personalized system to meet your specific processing requirements.

Metal Recovery & Refining Systems

Built Around Your Business

Looking to transform your scrap metal into a source of revenue, sustainability, and operational efficiency? You’re in the right place. At Engineered Recycling Systems (ERS), we specialize in designing and building advanced metal recovery and refining systems tailored specifically to your operation’s needs.

Whether you’re exploring the benefits of recycling for the first time or already committed to integrating a system, our team will partner with you to develop a solution that not only meets your production goals—but also pays off financially.

Every system we deliver is engineered around your materials, facility layout, and long-term business strategy. From copper wire, meatballs, and ASR to e-waste PCBs and aluminum scrap—we help you reclaim value from even the most complex streams.

Our goal? Cleaner processes, higher yields, and smarter profits.

Let’s engineer a system that fits your operation, your budget, and your future.

📩 Reach out via our contact form and take the first step toward your next-generation recycling solution.