Metals Processing and Scrap Metal Recycling Systems

Comprehensive Metals Processing Systems for Efficient Scrap Recycling

At Engineered Recycling Systems (ERS), we specialize in delivering cutting-edge metals processing systems designed to maximize recovery, streamline operations, and minimize environmental impact for scrap recyclers and metal processors worldwide. Our fully integrated, turnkey solutions are engineered to handle a wide variety of metal scrap streams — including copper, aluminum, ferrous scrap, shredder residue, electronic scrap, and more.

Unparalleled Expertise in Metals Processing and Recycling

With decades of industry leadership, ERS combines advanced engineering with real-world experience to design, build, and install complete metals processing lines. From initial consultation and system design through equipment supply, installation, and ongoing service, ERS stands as a trusted partner dedicated to delivering reliable, high-performance recycling solutions tailored to your unique needs.

Our portfolio spans everything from copper wire and cable chopping systems, to black mass recovery, ASR fines processing, and heavy-duty shredder wire and cable lines. By partnering with best-in-class manufacturers like WEIMA and Guidetti, we ensure that every system integrates the latest technology and meets the highest quality standards.

Advanced Technologies for Superior Metal Recovery

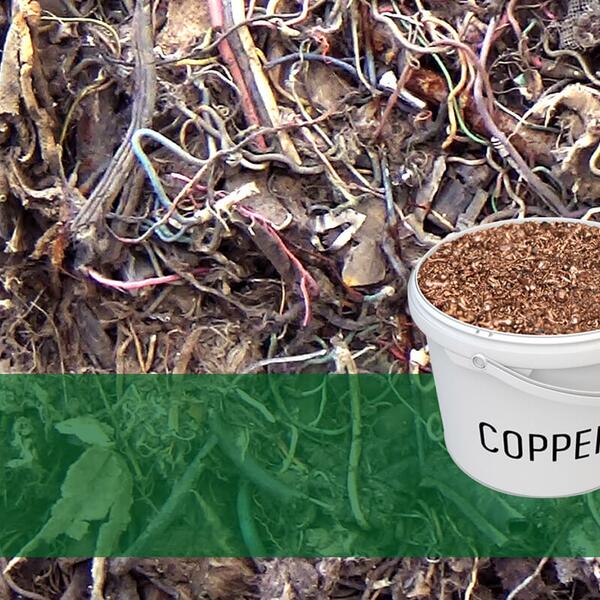

Copper Wire & Cable Processing

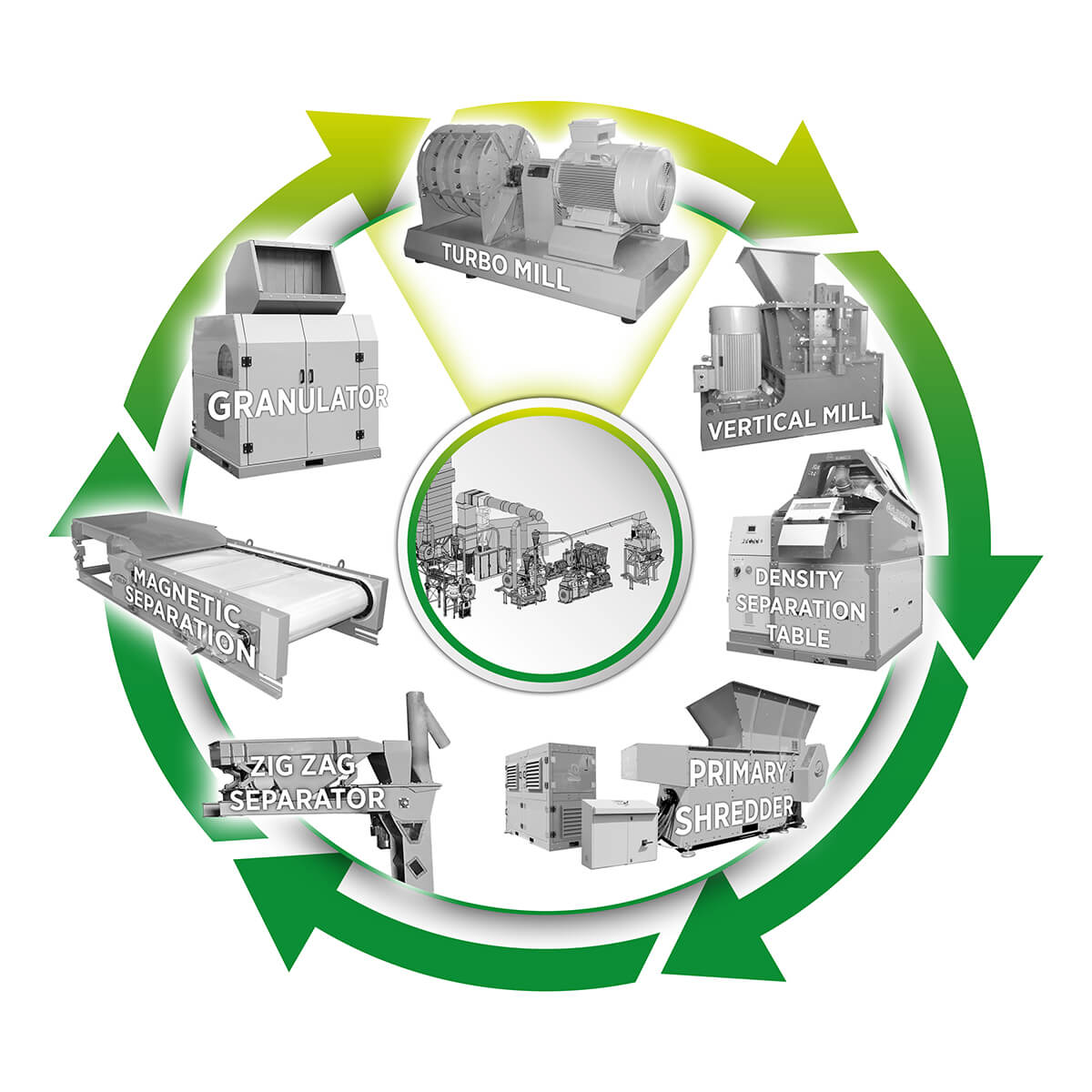

ERS copper wire chopping and granulation systems are designed to efficiently process insulated copper and aluminum wire scrap. Our equipment ensures maximum metal liberation while preserving copper integrity for high-purity recovery. Key components include heavy-duty shredders, cable granulators, and advanced magnetic and eddy current separators.

Black Mass and Battery Recycling

As the electric vehicle and battery recycling market grows, ERS leads with innovative black mass recovery systems that efficiently extract valuable metals like lithium, cobalt, and nickel from spent batteries. Our solutions enable safe, cost-effective battery material recycling aligned with environmental regulations.

ASR (Auto Shredder Residue) Processing

Our ASR fines processing lines extract metals and plastics from complex shredder residues with minimal loss. These turnkey systems use state-of-the-art separation technologies to recover precious metals and reduce landfill waste.

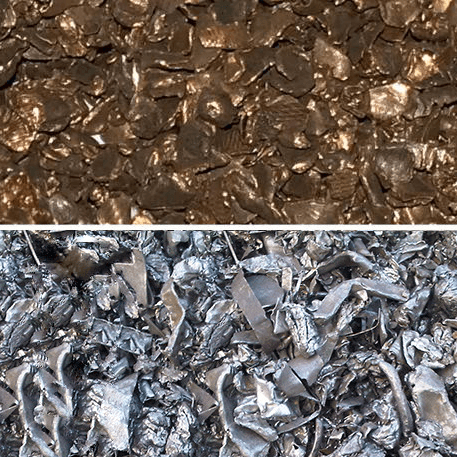

Shredder Wire & Cable Recycling

For large-scale operations, ERS delivers robust shredder wire and cable chopping lines capable of processing high volumes of scrap. These lines include crushers, granulators, metal separators, and dust collection systems, optimized for maximum throughput and recovery.

Midlings & Tailings Processing

ERS midlings and tailings systems recover metals from the intermediate and residual fractions of shredding and smelting processes. These solutions improve scrap value and environmental compliance by reducing contaminants and maximizing metal extraction.

Complete Turnkey System Solutions

At ERS, we understand that no two recycling facilities are the same. That’s why we focus on delivering customized turnkey metals processing systems tailored to your operational goals and facility layout. Our comprehensive services include:

System Design & Engineering

Tailored process flow design, equipment specification, and plant layout optimized for your material types and production targets.

Equipment Integration

Seamless assembly of shredders, separators, conveyors, dust control units, and automation systems into a cohesive, efficient production line.

Installation & Commissioning

On-site installation with rigorous testing and training to ensure smooth startup and optimal performance.

Ongoing Support & Maintenance

Responsive service, spare parts supply, and upgrades to keep your metals processing system running at peak efficiency.

Environmental & Safety Compliance

ERS systems are built to meet the strictest safety and environmental standards. Our dust collection and filtration units minimize airborne particulates, protecting workers and surrounding communities. We incorporate OSHA and EPA compliance measures throughout system design, ensuring your facility meets all regulatory requirements while maintaining high productivity.

Why Choose Engineered Recycling Systems?

Decades of Proven Expertise

ERS’s team consists of industry-leading engineers and system integrators with deep knowledge in metal recovery and recycling technologies.

Unrivaled Equipment Partnerships

We collaborate with premium equipment manufacturers like WEIMA and Guidetti to deliver reliable, high-quality machinery.

End-to-End Solutions

From concept to commissioning and beyond, ERS takes full system responsibility to ensure your success.

Customized for Your Needs

Our flexible modular designs adapt to a wide range of scrap types, throughput capacities, and budget constraints.

Maximized ROI

High recovery rates, reduced downtime, and efficient operations mean faster payback and greater profitability.

Industries We Serve

ERS metals processing systems serve a diverse range of industries, including:

Scrap metal recyclers and processors

Automotive dismantlers and recyclers

Electronic waste (e-scrap) recyclers

Manufacturing and industrial waste processors

Battery recycling facilities

Demolition and construction waste handlers

No matter the scale or complexity, ERS has the expertise and technology to help you unlock maximum value from your scrap streams.

Explore Our Metals Processing Solutions Today

Discover how ERS can transform your scrap recycling operations with advanced metals processing systems engineered for efficiency, compliance, and high recovery rates. Browse our full lineup of systems and equipment, view case studies, and request a consultation with our expert team.

Engineered Recycling Systems — Your partner in advanced metals processing and sustainable recycling solutions.

Separate & Recycle

Product Line of Metal Recycling Systems

As copper prices continue to stay strong you need a strong partner.

Engineered Recycling Systems is the leader in metals refining systems and scrap metals recycling equipment.

Call us today for a personalized system to meet your specific processing requirements.