The Game Changer: Continuous Cleaning Modular CCM® OCT Filter

ERS CCM® OCT Patented Filter is the most innovative filter and paper trim system in the market.

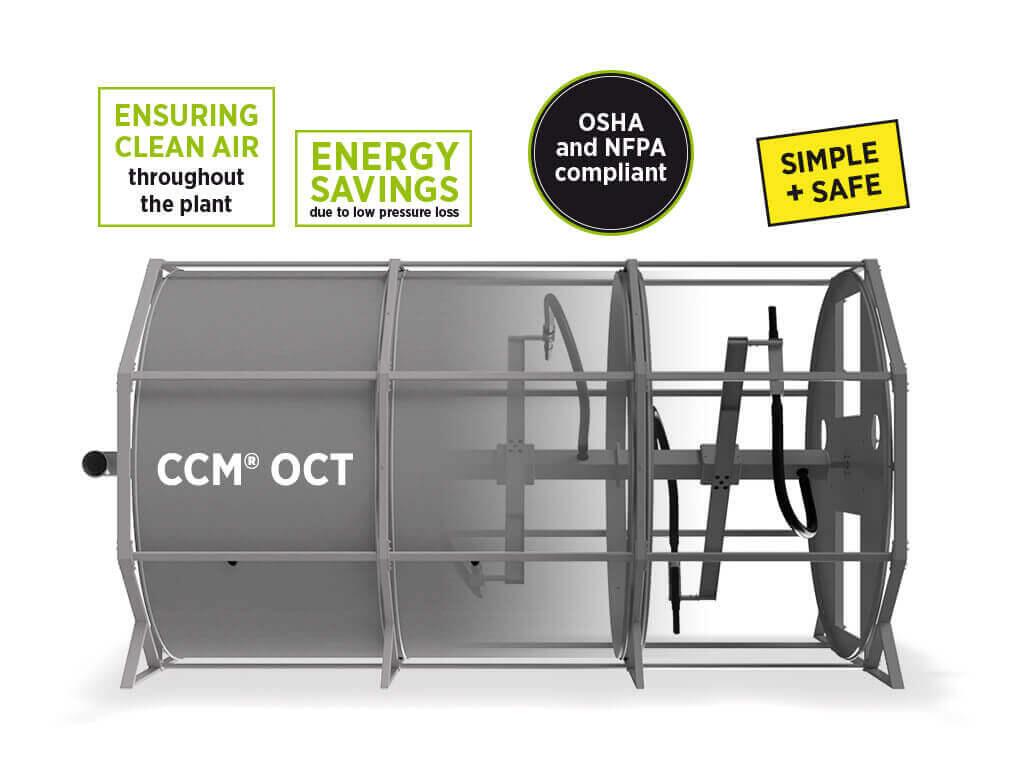

The design of the Continuous Cleaning Modular CCM® OCT Filter Dust Collection System completely departs from conventional filter systems. The CCM® OCT Filter is stationary and can be placed inside the production facility. The incoming air flows from the inside to the outside, leaving the drum through the whole filter surface.

The unique modular design of the CCM® OCT Filter ensures that your filter will meet even the most demanding requirements and can be modified based on future demands. The system can be installed and commissioned within a short time compared to that of conventional filter systems. It can be mounted quickly and efficiently in the smallest of spaces and supplemented by filter segments at any time.

In response to COVID-19, the cleanliness of your facility needs the ERS CCM® OCT Filter now more than ever.

CCM® OCT Filter operate under positive pressure and therefore do not require an enclosure as many other systems do. The airstream, which contains dust, enters the filter drum through the dust inlet on the front or back of the filter. Vacuum nozzles rotate and move horizontally inside the drum. Anti-static suction nozzles inside the filter drum continuously vacuum dust and waste from the fine filter media.

Little air is required to clean the fine filter medium as the suction nozzles are very efficient. The specially designed anti-static suction nozzles touch the fine filter media, which guarantees high and efficient cleaning. All CCM® OCT filters are fully grounded to prevent static buildup. The CCM® OCT filters are perfectly suitable for energy-efficient filtration of large volumes of dust-laden air.

with an application in various industrial applications:

- Corrugated Industry Dust Collection System

- Paper Manufacturing Dust Filtration

- Tissue paper de-dusting

- Metals Recycling Dust Collection

Advantages over conventional dust filtration technology

Smart, Safe, and Efficient Filtration—Built for Performance

- Precision Airflow Control – Modular design adapts seamlessly to your needs

- Minimal Downtime – Inspect the filter during operation, no full shutdown required

- Energy-Smart Efficiency – Low pressure loss keeps costs down

- Built-In Safety – No explosion venting or high-speed abort gates needed

- Designed with OSHA and NFPA guidelines in mind to support safe and compliant operation.

- More Uptime, Less Hassle – Reduced maintenance, lower labor costs, and smoother production

- A Cleaner, Safer Workplace – Enhanced filtration for a healthier environment

Safety Always Comes First

✅ No Risk of Critical Dust Concentration – Designed for maximum control ✅ Hassle-Free Maintenance – No ladders or lifts needed ✅ Smart Sensors & Controls – Monitors and maintains a safe working environment

The CCM® OCT Filter Medium

has high dust collection efficiency,

low resistance

and a long service life