Innovation in Action – ERS News & Projects

ERS news and recycling projects showcase real-world system installations, cutting-edge technology upgrades, and customer success stories — proving how Engineered Recycling Systems delivers measurable results across industries.

04. Nov 2025

ERS Dust, Scrap, and Trim Collection Systems Support Clean Tissue Converting from Parent Roll to Log Saw

0

03. Nov 2025

ERS Dust and Scrap Collection Systems Optimize Tissue Converting Efficiency with CCM® OCT Filters

0

30. Oct 2025

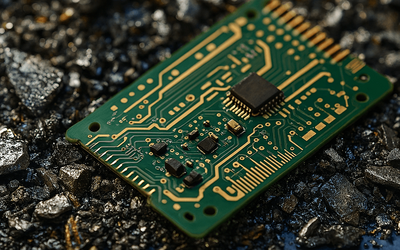

ERS Delivers Custom E-Scrap Recovery Systems for Rare Material Extraction from PCB Boards

0

28. Oct 2025

Clean Cut: ERS Finishes Integrated Scrap and Dust Solution for Göpfert RDC HBL

0

21. Oct 2025

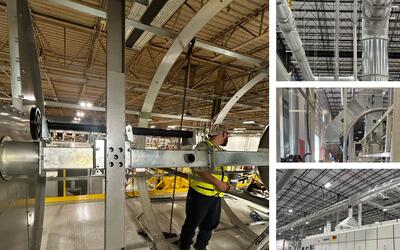

ERS Begins Installation of Dust & Scrap Collection System for Göpfert RDC HBL Operator

0

21. Oct 2025

Meet Engineered Recycling Systems at CorrExpo 2025 — Booth 743

0

13. Oct 2025

Tailings and ASR Systems for Scrap Value Recovery

0

09. Oct 2025

In Progress: CCM® OCT Filter Installation for Göpfert HBL VTS System

0

07. Oct 2025

Dust Collection Solutions for OEMs Serving Corrugated Box Manufacturers

0

02. Oct 2025

02. Oct 2025

ERS Redefines Metal Recovery: In-House ASR Processing vs. Outsourcing

0

26. Sep 2025

ERS Systems Ready for New ReMA Vesper Standard in Aluminum Recovery

0