Innovation in Action – ERS News & Projects

ERS news and recycling projects showcase real-world system installations, cutting-edge technology upgrades, and customer success stories — proving how Engineered Recycling Systems delivers measurable results across industries.

27. Jun 2025

This Week at ERS: Turning Scrap into Strategy

0

26. Jun 2025

ERS Systems Are Working in Facilities Near You

0

26. Jun 2025

Engineered Recycling Systems Ensures Reliable Parts Availability with Fully Stocked Warehouse

0

17. Jun 2025

Field Service That Delivers—Every Bolt, Every Time

0

17. Jun 2025

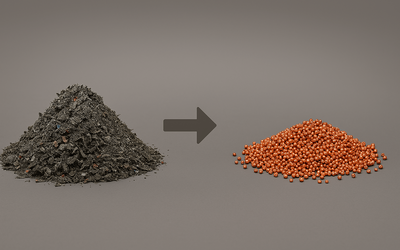

Engineered Recycling Systems Unveils Next-Generation ASR Recovery Technology

0

29. May 2025

Engineered Recycling Systems’ CCM® OCT Filter: A Safer, Smarter Alternative to Traditional Baghouse Filters

0

29. May 2025

Engineered Recycling Systems Drives Innovation in Industrial Recycling

19. May 2025

ERS Invites Customers to Atlanta Test Facility

20. Jan 2025

Welcome to the ERS Team: Mark Haire Joins ERS’ Technical Sales Staff

0