Tackling Dust Challenges in the Tissue Industry with ERS

Engineered Recycling Systems (ERS): Your Partner in Dust Control Excellence

In the tissue industry, effective dust control is crucial for several reasons:

Safety Hazards

Dust accumulation in tissue manufacturing facilities can create significant safety risks, including fire and explosion hazards. Tissue dust is highly flammable, and when it accumulates, it can lead to dangerous conditions. Effective dust collection systems help mitigate these risks by continuously removing dust from the environment.

Health Risks

Workers in tissue manufacturing plants are exposed to airborne dust, which can lead to respiratory issues and other health problems. A robust dust collection system ensures cleaner air, protecting the health and well-being of your workforce.

Machine Performance

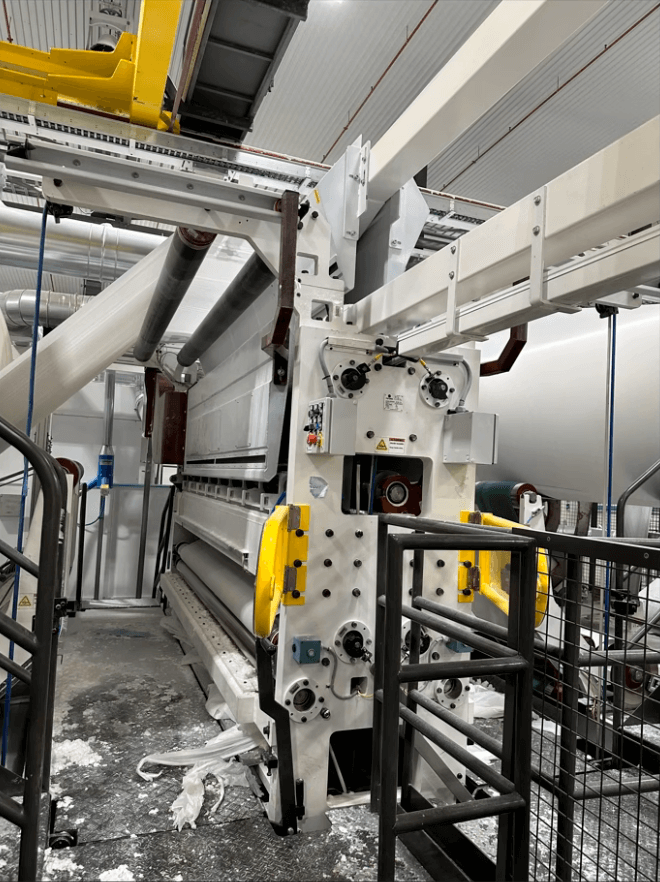

Dust can accumulate on machinery, leading to frequent clean-ups, unexpected shutdowns, and reduced efficiency. By implementing an efficient dust control system, you can maintain optimal machine performance and reduce downtime.

Product Quality

Dust contamination can compromise the quality of tissue products, leading to defects and customer dissatisfaction. Effective dust removal ensures that your products meet the highest quality standards.

Our Expertise

At ERS, we bring together a team of top engineers and system integrators dedicated to providing the tissue industry with cutting-edge dust control solutions. With a wealth of industry knowledge and expertise, we have developed the Continuous Cleaning Modular CCM® OCT Filter – a groundbreaking system designed to address the specific challenges faced by tissue converting facilities.

Key Benefits for the Tissue Industry

- Efficient Filtration: The CCM® OCT Filter excels in energy-efficient filtration of large volumes of dust-laden air, ensuring the highest quality standards for your tissue products.

- Compact Footprint: Our filters require a significantly smaller footprint compared to alternative technologies, making them ideal for the space constraints often found in tissue and paper converting facilities.

- Environmental Sustainability: ERS’ CCM® OCT filters do not rely on compressed air or water, contributing to both cost savings and environmental sustainability.

Customized Solutions for Tissue Mills

We recognize that each facility is unique, and our solutions are tailored to meet your specific requirements. Whether you are dealing with safety hazards, machine issues, or health risks associated with dust, ERS has the expertise to provide a customized dust control system that aligns with your production needs.

Why Choose ERS

- Proven Technology: The CCM® OCT Filter is a testament to our commitment to innovation and efficiency, providing unrivaled performance in dust control.

- Simplified Maintenance: With a simple design and the use of standard hand tools for maintenance, our systems ensure ease of operation, reducing downtime and labor costs.

- Safety Compliance: ERS solutions adhere to workplace safety, health, and fire protection guidelines, ensuring a secure and compliant work environment.

- Service and Spare Parts: In ERS’ 55,000 square foot Atlanta facility, we stock all major parts and house a service department that is standing by to meet your needs.

Partner with ERS for Dust Control Excellence

ERS is not just a supplier; we are your dedicated partner in overcoming dust challenges in the tissue industry. Trust us to deliver turnkey solutions that enhance efficiency, improve air quality, and elevate the overall performance of your plant.

For more information on how ERS can help you solve your dust problems, contact us at info@engineeredrecycling.com.