Engineered Recycling Systems designs and builds high‑performance material‑handling systems for two core industrial sectors: Paper Converting and Metals & Recycling. We engineer complete solutions for dust collection, trim and matrix removal, pneumatic conveying, metals recovery, and battery‑material processing — all built for clean operation, stable airflow, and long‑term reliability.

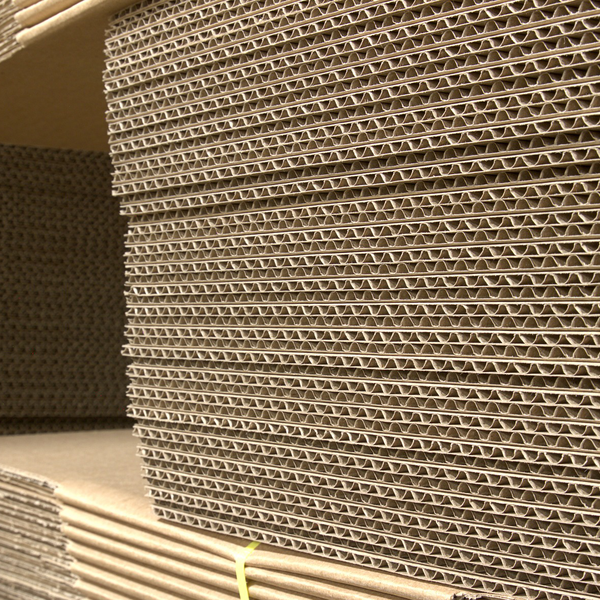

Paper Converting Systems

ERS supports tissue, towel, corrugated, boxboard, and flexible packaging operations with engineered dust collection and trim removal systems designed for high‑speed production. Our solutions stabilize airflow, capture fine particulate at the source, and keep converting floors clean and efficient — including specialized systems for TAD‑based tissue products.

Metals & Recycling Systems

For scrap processors, wire and cable recyclers, ASR facilities, and emerging battery‑material operations, ERS delivers complete metals recovery and separation systems. From copper wire and e‑scrap to black mass recovery from lithium‑ion and EV batteries, our systems are engineered for purity, throughput, and dependable performance.

Whether you’re optimizing a single process or building a plant‑wide solution, ERS provides the engineering, equipment, and support to keep your operation running clean, safe, and productive.

Engineered for performance. Built for real‑world production.

Latest News

Upcoming Events

2100 Costa Del Mar Rd, Carlsbad, California, USA

1901 Convention Ctr Dr, Miami Beach, FL 33139

623 Union St, Nashville, TN 37219, USA.