Efficient Magnetic Separation for Metal Recovery

ERS provides cutting-edge magnetic separation solutions designed to optimize material purity and enhance metal recovery. Our systems efficiently remove ferrous contaminants from scrap streams, ensuring high-quality processing and minimizing equipment wear.

Key Benefits of ERS Magnetic Separation:

-

Precision Metal Extraction – Effectively separates ferrous materials from mixed scrap

-

Improved Equipment Protection – Prevents metal contamination from damaging shredders and mills

-

Optimized Workflow – Enhances efficiency by streamlining material separation

-

Custom Configurations – Designed for seamless integration with your processing line

-

Low Maintenance & High Reliability – Engineered for durable and continuous operation

Whether integrated with shredding, baling, or trim removal systems, ERS magnetic separation technology ensures consistent, reliable metal sorting for improved recyclability and resource efficiency.

Eddy Current Separator

Used primarily with non-ferrous aluminum metals, our eddy-current separators are proven to cut aluminum loss and labor costs associated with sorters

Drum Magnet

Designed to efficiently and cost effectively remove large and small pieces of ferrous materials from material processing lines.

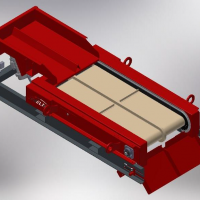

Cross Belt Magnet

Designed to pull ferrous and tramp metals from your recycling lines and any other conveyor configurations where metals need to be extracted

High Gauss Magnet

Our overhead self-cleaning, stationary and permanent high-gauss magnets are designed to pull ferrous and tramp metals from your recycling lines and any other conveyor configurations where metals need to be extracted.

Head Pulley Magnet

Available in numerous sizes, widths, diameters and magnet types, our head-pulley magnets can be designed to fit your specific application requirements.