Carboard Shredder

Economical solutions for shredding and processing! Our hammer mills are the answer to the challenge of selectively shredding hard and brittle materials. Reducing transportation costs, compressing material for feeding to existing pressed-waste containers or baling presses, or shredding of material for conveyor belt feeding are good reasons for deploying a cardboard shredder.

With the EKZ cardboard shredder and FKZ paperboard shredder, ERS two rugged machines offer 100% process reliability in a range of form factors. Whether you need to shred packaging or process cardboard waste for feeding into existing conveyor systems, ERS can always offer you a perfect solution tailored to your requirements.

Space-saving space cardboard box disposal

Light, easy to use and, most importantly, fully recyclable – cardboard boxes are becoming increasingly popular as packaging material The members of the Corrugated Cardboard Industry Association (Verband der Wellpappen-Industrie) alone sold around 1.9 billion square meters in the first quarter of 2017. However, recycling used cardboard boxes can be problematic, not least because the folded cardboard boxes are becoming increasingly large and require a lot of space. Therefore it is useful for packaging manufacturers and service providers to use a special shredding facility to shred cardboard boxes and to simplify the disposal process. Thanks to its low-maintenance chain drive, wear-resistant tearing segments and a scraper system that was specially designed for this application field, it has high availability and is extremely reliable.

The high demand, particularly for cardboard solutions, creates a logistical challenge: Several tons of cardboard need to be shredded every month. In the past, the flattened waste cardboard came directly out of the production machines without being shredded by a cardboard shredder and was fed into a paper container.

Tearing segments reduces size to less than ten percent

The main requirements made of the system were that it could handle corrugated and solid cardboard and that it could fit into the tight space available. Engineered Recycling Systems recommended a cardboard shredder from the EKZ series, which comes in a number of sizes and can therefore accommodate a range of different conditions. Depending on their size, the systems can reduce the cardboard packaging with a width of up to 2,400 mm and a height of approximately 650 mm, as well as flat cartons with layer heights of up to 50 mm. The end product is approximately 200 x 300 mm and 300 x 400 mm in size and is therefore ideal for compressing in the downstream press. While cardboard boxes that have not been shredded are much more difficult to compress, this method can achieve a compact end result that requires very little storage or transportation space, therefore significantly reducing costs.

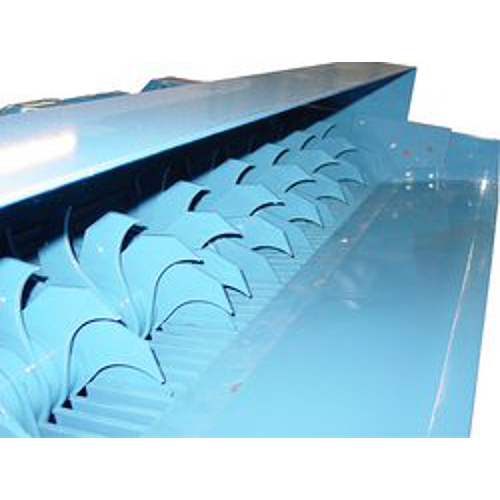

For shredding, the cardboard shredder uses two drive shafts with independent drive units: a slow feeder and a faster shredder that reduces the cardboard boxes to the desired size. Segments made of special tear-proof steel are organized around the shredder rotor so that they are alternately inclined outward and inward. As the shaft turns it creates a whirling motion that ensures the required shredding effect. The large rotors are 520 mm in diameter and are therefore capable of handling large cardboard boxes without any problems; they can even shred polystyrene and fruit boxes. Furthermore, the feeder and shredder rotors are fitted with a special scraper system that stops the material becoming wrapped around the shafts and ensures a steady feed.

Reliable shredding of cardboard waste for direct extraction to the conveyor belt system

Engineered Recycling Systems also has available the FKZ fine cardboard shredder as the ideal addition to the EKZ cardboard shredder. Thanks to its efficient shredding process, this is perfect for trouble-free extraction at the source of waste generation. Materials like cardboard waste from production machines or automatic cutting presses can be fed directly into existing conveyer belt systems. This means that ERS offers a complete system for highly efficient handling of cardboard waste. Different machine sizes allow efficient and made-to-measure machine concepts to suit any cardboard volumes.