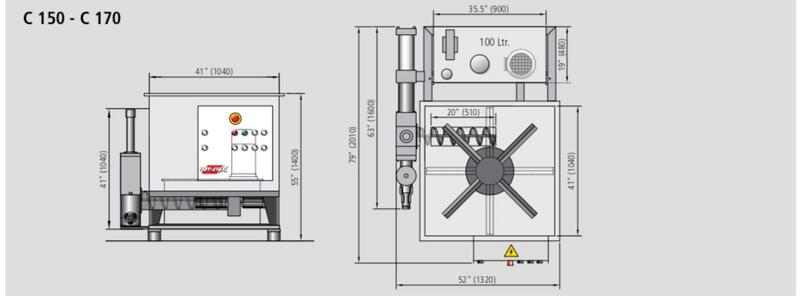

Briquette Press C 150 / C 170

Briquette Presses are used for further compaction of materials such as wood chips, sawdust, shavings, paper dust, etc. Most machines are installed directly under dust collection systems. Without the use of any glues or adhesives, the press creates a solid briquette which looks similar to a hockey puck.

The main benefit of using a briquette press is to compress loose materials. Most briquettes can also be used as a heat source. Our presses include an impressive array of optional features, including a level sensor, hydraulic oil heating and cooling and an automatic length adjustment.

The Briquetting Process

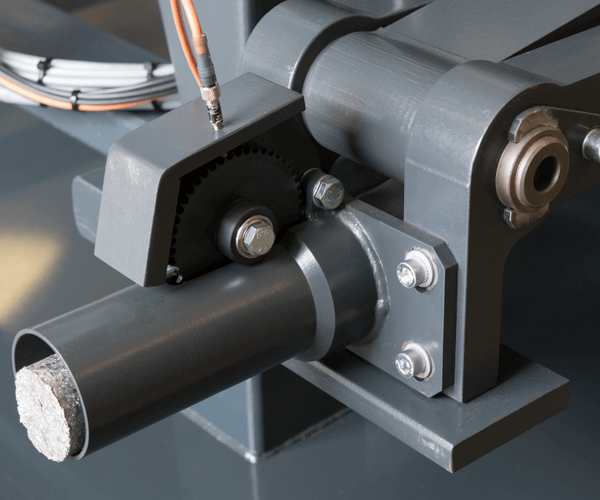

Material is fed into the hopper either by hand or in conjunction with a dust collection system. Simply turn on the machine and the agitator will start to spin, pushing the material into an opening at the bottom of the unit. An auger fills the pressing chamber and material is transferred into the cylinder where it is densified into a briquette. No glues or adhesives are used as a binding agent, leaving you with a clean, reusable product.

There’s a lot to be said for briquetting

• Reduction of waste volume by up to 90% – resulting in considerable saving of disposal, transport and storage costs.

• Production of high quality secondary raw materials and briquettes that are high in heating value.

• Considerable reduction of fine dust and pollutants through the compression of shavings and dusty materials into clean, compact briquettes.

• Reduction in the danger of fires and explosions by briquetting potentially flammable waste – an economic alternative to costly fire prevention measures

| C 150 | C 170 | |

|---|---|---|

| Weight | 1,760 lbs (800 kg) | 2,205 lbs (1,000 kg) |

| Briquette Diameter | 2" (50 mm) | 2.8" (70 mm) |

| Hydraulic oil quantity | 26.5 g (100 L) | 26.5 g (100 L) |

| Hydraulic motor | 9 hp (6.6 kW) | 12 hp (9 kW) |