Innovation in Action – ERS News & Projects

ERS Industrial Project News from Engineered Recycling Systems shares real-world updates, installations, and system upgrades across metals processing, paper converting, and dust control. This page highlights customer success stories, new technologies, and behind-the-scenes insights from ERS field teams and engineering partners.

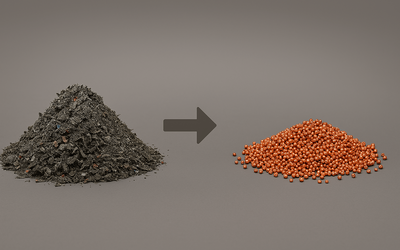

In the metals sector, ERS has recently completed turnkey installations for copper wire chopping, aluminum separation, and rare earth recovery from printed circuit boards. These projects feature advanced granulation lines, magnetic and eddy current separators, and air classification systems designed to isolate high-value fractions from complex scrap. Each system is tailored to the facility’s layout and material flow, with rapid ROI and minimal downtime.

ERS also delivers major innovations in the paper converting industry. Recent news includes dust and trim removal systems for rotary die cutters, Flexo Folder Gluers, and corrugated production lines. These installations feature the CCM® OCT Filter—a fully enclosed, low-maintenance solution that operates without compressed air or regeneration cycles. OEMs and machine builders are now integrating ERS dust control into their standard offerings.

Across industrial scrap handling, ERS continues to retrofit and upgrade non-ERS systems. From pneumatic transport lines to magnetic separation platforms, ERS engineers deliver modular solutions that improve air quality, reduce maintenance, and meet evolving compliance standards. Field service teams provide on-site diagnostics, training, and performance tuning to ensure long-term reliability.

ERS Industrial Project News is updated regularly with new case studies, system highlights, and customer feedback. Whether you're in metals, paper, or dust-intensive environments, this page offers a window into how ERS systems are solving real-world challenges and driving operational excellence.