Guidetti Reco Mill Line

Guidetti Reco Mill Line from Engineered Recycling Systems (ERS) is a CE-certified solution designed to recover copper from plastic tailings generated during cable granulation. This compact, high-efficiency system ensures that no valuable metal is lost in the final stage of processing, delivering up to 100% copper recovery from mixed waste streams.

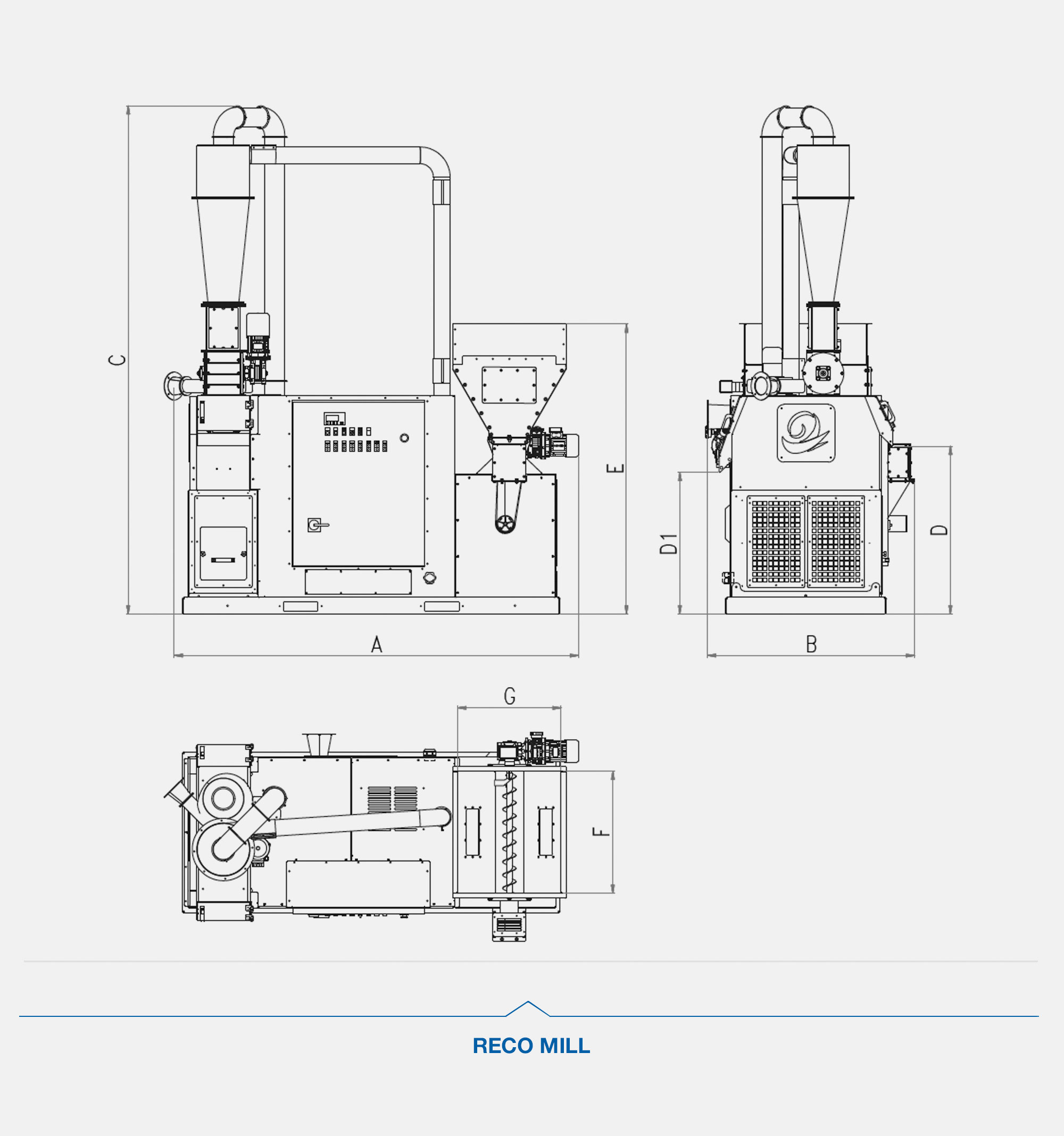

The Reco Mill Line includes three models—Reco Mill 15, Reco Mill 50, and Reco Mill 100—each engineered for specific throughput and power requirements. The Reco Mill 15 offers 120–200 kg/h capacity with 12.5 kW installed power and a footprint of 2461 × 1260 × 3100 mm. The Reco Mill 50 delivers 400–600 kg/h at 40 kW, while the Reco Mill 100 reaches 800–900 kg/h with a 3800 kg frame and integrated dry separation. All models are CE-compliant and designed for easy integration with existing granulation systems.

ERS integrates the Reco Mill Line as a post-processing stage following primary cable granulation. Tailings that would otherwise be discarded—typically containing residual copper dust or fine particles—are reprocessed through the Reco Mill’s zig-zag separator, turbo pulverizer, and dry separation table. This ensures that even the smallest copper fragments are recovered, boosting total system efficiency and profitability.

Each Reco Mill unit is built for compact installation and low maintenance. The system includes a programmable PLC, sealed bearings, and reinforced housings to ensure long-term durability. Soundproofed enclosures and integrated dust filtration support clean, quiet operation in compliance with environmental and workplace safety standards.

ERS configures each Reco Mill installation to match facility layout, material flow, and production goals. Whether you're upgrading an existing Sincro, Sincro Eko, or Sincro Mill line, or adding recovery to a third-party granulator, the Reco Mill Line delivers consistent performance and high recovery rates. Its compact design and low energy consumption per ton of processed tailings make it a cost-effective choice for recyclers seeking to maximize yield.

The Reco Mill Line is CE-certified and built to meet European safety and environmental standards. Maintenance access is streamlined through hinged panels and intuitive controls, while optional components such as dosing conveyors and magnetic separators allow for tailored system configurations.

The advantages of the Reco Mill Line include zero tailings loss, reduced environmental impact, lower energy consumption per ton of recovered copper, and a rapid return on investment. These features make the Reco Mill Line one of the most advanced and operator-friendly copper recovery systems available.

By investing in the Guidetti Reco Mill Line from ERS, manufacturers gain a powerful solution for maximizing copper recovery from cable recycling. These machines are built to transform overlooked tailings into clean, valuable feedstock—supporting sustainable operations and profitable recovery.

| Technical Data |

Length | Width | Height | Weight | Power | Production |

|---|---|---|---|---|---|---|

| Reco Mill 50 |

3453 mm 135.9'' |

1450 mm 57.1'' |

4386 mm 172.7'' |

2220 kg 4894 lb |

40.0 kw 53.6 HP |

400-600 kg/h |

| Reco Mill 15 |

2461 mm 96.9'' |

1260 mm 49.6'' |

3100 mm 122.0'' |

990 kg 2183 lb |

12.5 kw 16.8 HP |

120-200 kg/h |