Single Shaft

Shredders

The all-rounders for any application!

Shredders for Metals Recycling

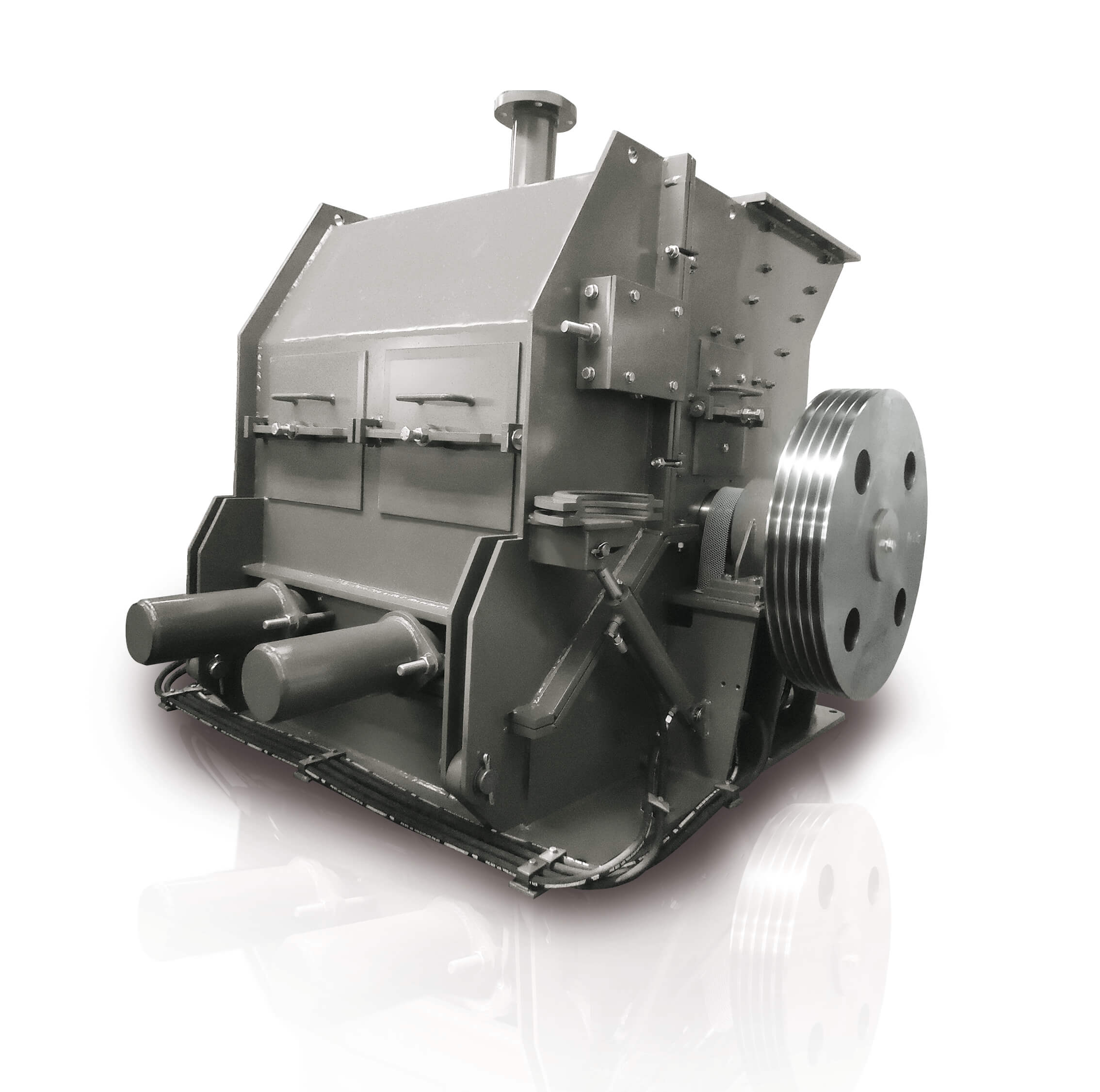

Shredders for metals recycling from Engineered Recycling Systems (ERS) are engineered to handle the toughest compressible materials in industrial scrap environments. These systems are built for high-efficiency reduction of mixed waste, tires, batteries, and ferrous and non-ferrous metals, delivering consistent performance and long-term durability.

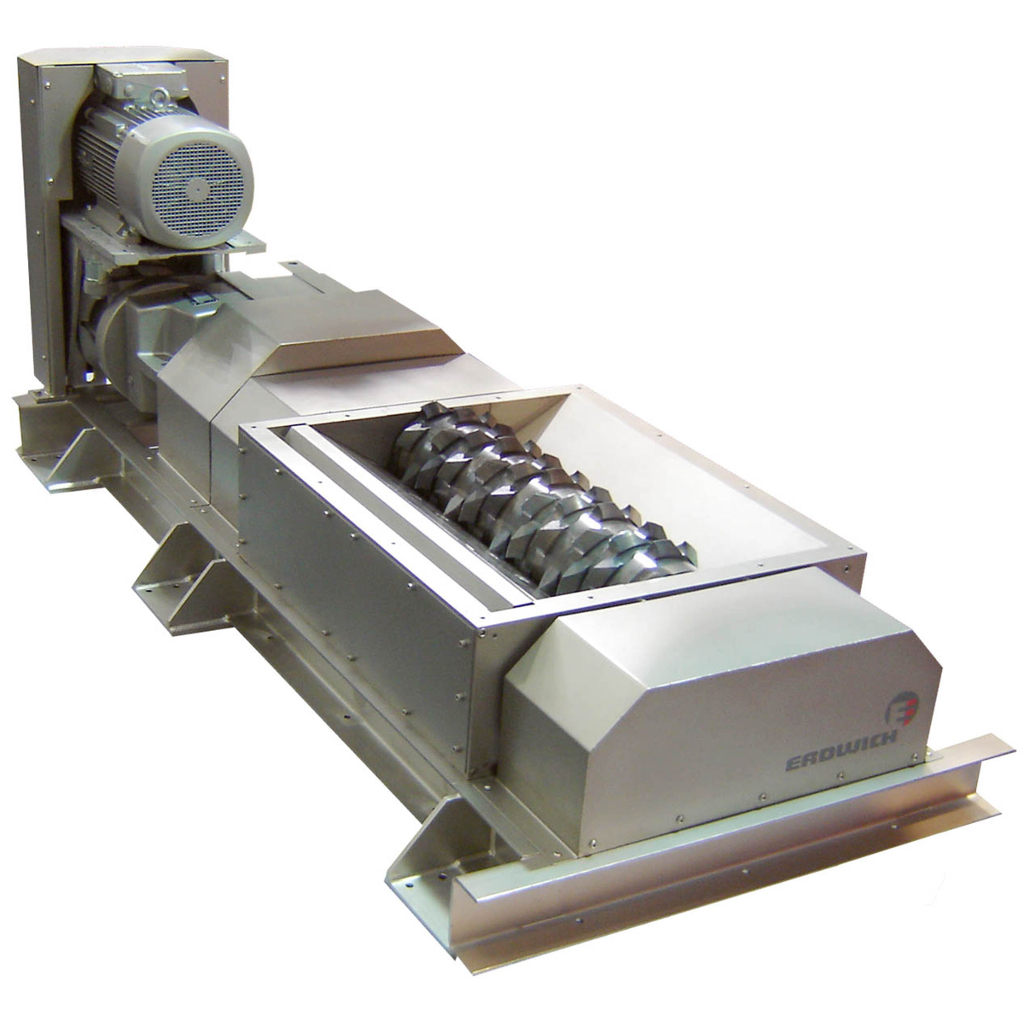

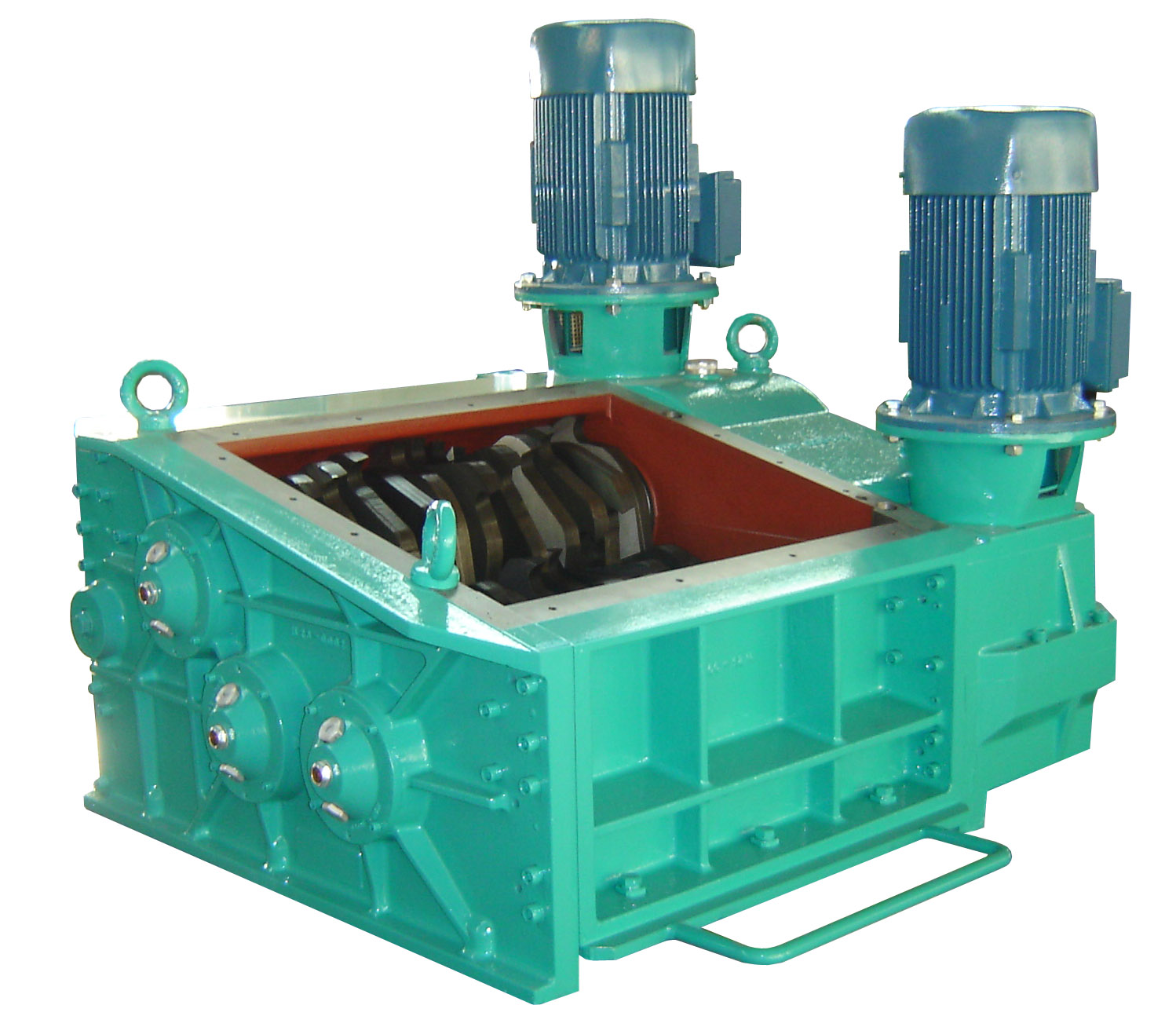

ERS shredders are designed with rib-reinforced housings and precision CNC machining to maintain shaft alignment and gearbox-to-mainframe stability. This level of engineering ensures tighter cutter stack arrangements, greater versatility, and reduced wear over time. Whether you're processing dense metal scrap or composite waste streams, ERS shredders deliver the torque, throughput, and reliability required for continuous operation.

Each shredder unit is tailored to the specific demands of the facility, with options for bulk-fed or conveyor-fed configurations. ERS works closely with clients to assess material types, volume requirements, and integration needs, designing systems that optimize energy use and maximize recovery rates. Our shredders are compatible with downstream mills, separators, and dust collection systems, forming a complete metals processing line.

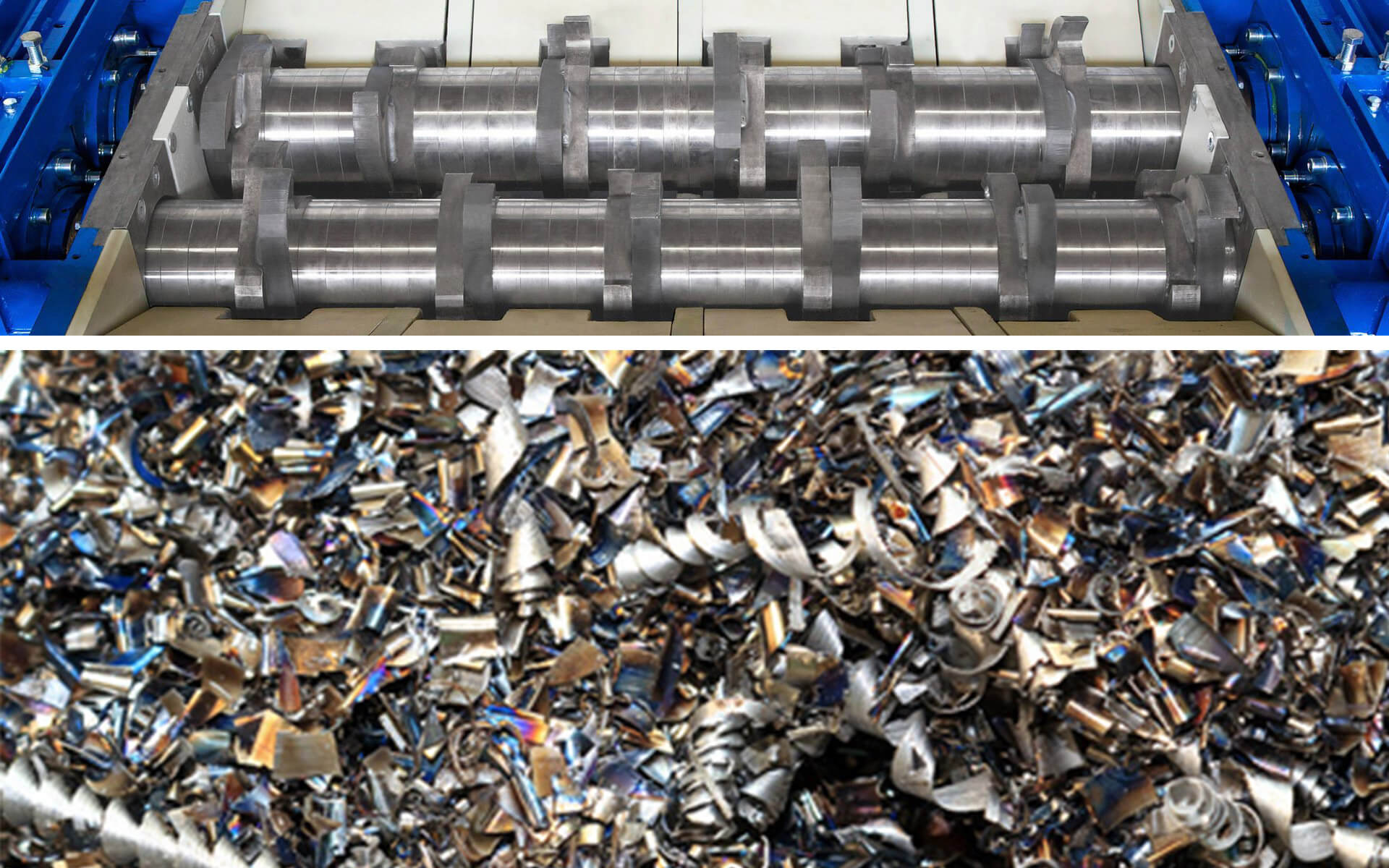

The shredding process begins with aggressive material intake, followed by controlled fragmentation through hardened cutter stacks. These stacks are arranged to deliver uniform particle sizing and efficient liberation of bonded materials. ERS shredders are particularly effective in preparing feedstock for ASR processing, e-waste recycling, and fluff separation, where precision and consistency are critical.

Durability is a core feature of every ERS shredder. Rib-reinforced housings absorb vibration and resist deformation, while CNC-machined components ensure long-term alignment and minimal maintenance. This combination of structural integrity and precision engineering allows ERS shredders to operate under extreme loads without compromising performance.

Integration is seamless across ERS systems. Shredders are designed to work in tandem with hammer mills, turbo mills, and vertical mills, creating a unified workflow from initial reduction to final sizing. Control systems, conveyors, and dust extraction units are configured to match the layout and operational goals of each facility, ensuring smooth material flow and minimal downtime.

ERS shredders are trusted across the recycling industry for their ability to handle diverse scrap streams with consistent results. From automotive components and industrial batteries to tires and mixed metal loads, our shredders deliver the power and precision needed to transform waste into valuable feedstock.

By investing in shredders for metals recycling from ERS, manufacturers gain control over material quality, operational efficiency, and environmental compliance. Our systems are built to support sustainable recycling, reduce labor costs, and improve overall throughput. Whether you're upgrading a single line or building a full-scale processing facility, ERS delivers shredding solutions that meet the highest standards of performance and reliability.