Guidetti Sincro Mill Line

Guidetti Sincro Mill Line from Engineered Recycling Systems (ERS) delivers a CE-certified, ultra-compact solution for recycling copper and aluminum cables. Designed for simultaneous processing of rigid and flexible conductors without pre-selection, these granulators combine dry separation, low energy consumption, and modular integration to support clean, profitable metal recovery.

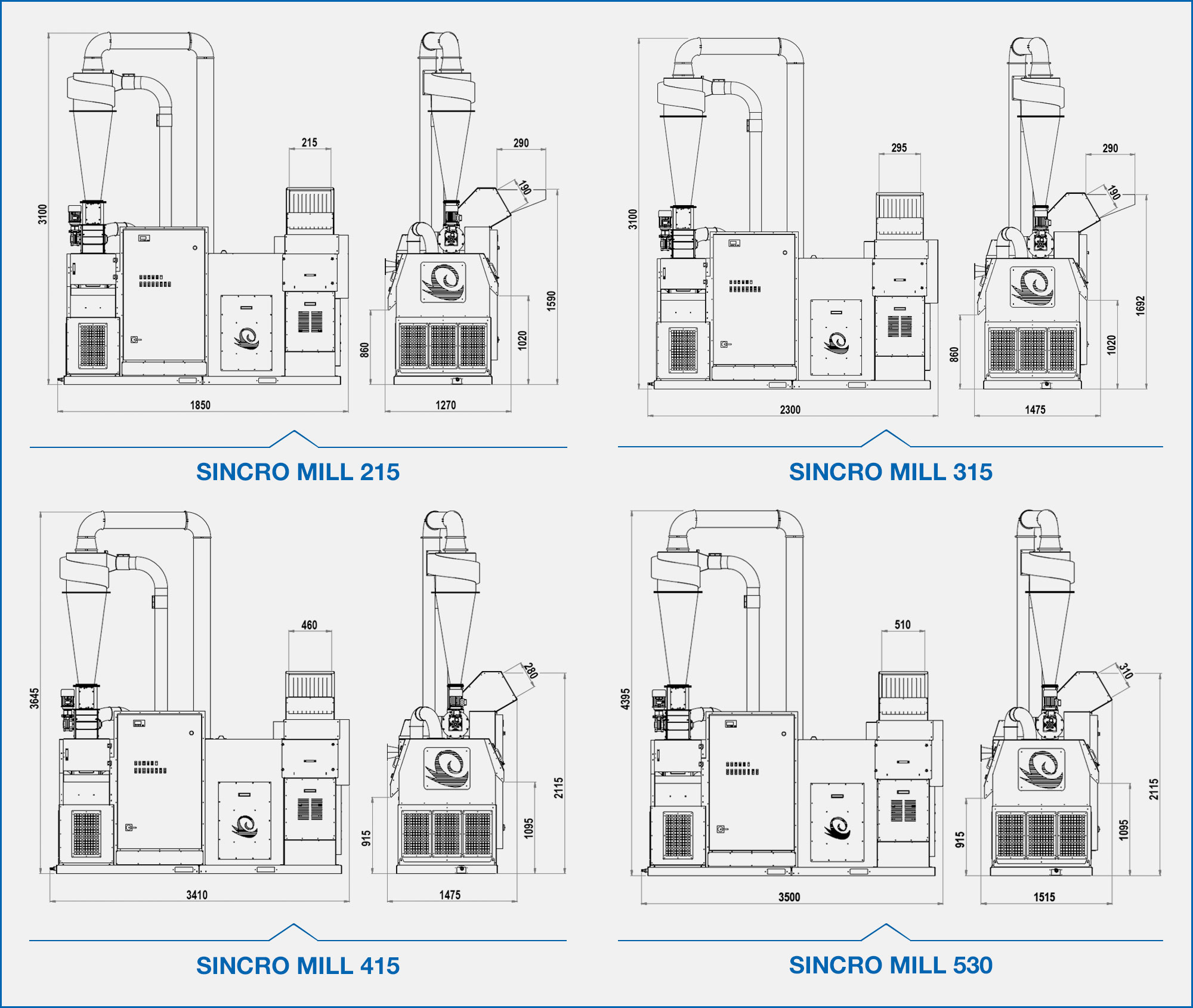

The Sincro Mill Line includes five models—Sincro Mill 215, 315, 415, 530, and 950—each engineered for specific throughput and power requirements. The Sincro Mill 215 offers up to 120 kg/h with a 12.5 kW motor and a footprint of 2300 × 1458 × 3084 mm. The Sincro Mill 315 delivers up to 180 kg/h at 23 kW, while the Sincro Mill 415 reaches 330 kg/h at 38 kW. The Sincro Mill 530 handles up to 600 kg/h with 53 kW installed power, and the Sincro Mill 950 tops the range with 800–900 kg/h throughput at 99.5 kW. All models are CE-compliant and built for manual or automated feeding.

ERS integrates these granulators into complete cable recycling lines, pairing them with Guidetti PMG pre-shredders, dosing conveyors, magnetic separators, and dust extraction systems. The Sincro Mill Line is designed to process copper and aluminum cables of any diameter, separating metal from insulation using a blade granulator, zig-zag separator, turbo mill, and dry densimetric table. Thick metals such as plugs and connectors are removed early in the cycle, while thin wires are further reduced to optimize separation quality and minimize metal loss.

Each unit features an extractable mill for rapid maintenance, reducing downtime and simplifying blade replacement. The soundproofed housing minimizes noise levels, making these systems ideal for facilities with strict acoustic requirements. Integrated dust filtration prevents airborne contamination, supporting clean air standards and safe operator conditions.

ERS configures each Sincro Mill installation to match facility layout, material flow, and production goals. Whether you're handling telecom cables, automotive harnesses, or mixed industrial scrap, these systems deliver consistent performance and high recovery rates. Their compact design and low energy consumption per ton of processed material make them a cost-effective choice for manufacturers, recyclers, and scrap processors.

The Sincro Mill Line is CE-certified and built to meet European safety and environmental standards. Maintenance access is streamlined through hinged panels and intuitive controls, while sealed bearings and reinforced housings ensure long-term durability. Optional components include rotary valves, dosing conveyors, and dust collection systems, allowing each installation to be tailored to specific material streams and recovery goals.

The advantages of the Sincro Mill Line include dust emissions compliant with current legislation, reduced acoustic pollution, lower energy consumption per ton of processed cable, lower maintenance costs, and constant production with over 99.9% purity of metals and plastics. These features make the Sincro Mill Line one of the most advanced and operator-friendly cable recycling systems available.

By investing in the Guidetti Sincro Mill Line from ERS, manufacturers gain a powerful, space-saving solution for cable recycling. These machines are built to transform complex scrap into clean, valuable feedstock—supporting sustainable operations and profitable recovery.

| Technical Data |

Length | Width | Height | Weight | Power | Production |

|---|---|---|---|---|---|---|

| SINCRO MILL 950 |

4516 mm 177.8'' |

4403 mm 173.0'' |

5500 kg 12,125 lb |

99.5 kw 133.5 HP |

1000-1200 kg/h 2200-2645 lb/h |

|

| SINCRO MILL 215 |

2300 mm 90.6'' |

1458 mm 57.4'' |

3084 mm 121.4'' |

970 kg 2138 lb |

12.5 kw 16.8 HP |

80-120 kg/h 176-264 lb/h |

| SINCRO MILL 315 |

2316 mm 91.2'' |

1475 mm 58.1'' |

3100 mm 122.0'' |

1200 kg 2646 lb |

20.0 kw 26.8 HP |

130-180 kg/h 286-396 lb/h |

| SINCRO MILL 415 |

3410 mm 134.3'' |

1472 mm 58.0'' |

3637 mm 143.2'' |

2500 kg 5512 lb |

38.0 kw 50.9 HP |

250-330 kg/h 551-727 lb/h |

| SINCRO MILL 530 |

3410 mm 134.3'' |

1515 mm 59.6'' |

4395 mm 173.0'' |

2700 kg 5952 lb |

53.0 kw 71.0 HP |

450-600 kg/h 992-1322 lb/h |