Efficient Magnetic Separation for Metal Recovery

ERS Magnetic Separation systems from Engineered Recycling Systems are CE-certified solutions engineered to extract ferrous and non-ferrous metals from industrial scrap streams. Designed for integration with shredders, balers, trim removal lines, and granulators, these systems improve material purity, protect downstream equipment, and enhance overall recycling efficiency.

ERS offers a full range of magnetic separation technologies, including cross belt separators, drum magnets, magnetic pulleys, and eddy current separators. Each system is configured to match the material flow, particle size, and recovery goals of the facility. Whether you're removing steel contaminants from shredded cable or recovering aluminum from composite scrap, ERS Magnetic Separation ensures consistent, high-efficiency performance.

The separation process begins with ferrous extraction using permanent or electro-magnetic systems. Cross belt separators remove tramp iron and steel from conveyor-fed material, while drum magnets and magnetic pulleys provide inline separation for finer or bulkier streams. For non-ferrous recovery, eddy current separators use high-speed magnetic rotors to eject aluminum, copper, and brass from mixed waste, delivering clean fractions ready for resale or refining.

ERS integrates magnetic separation into complete recycling lines, pairing it with pre-shredders, granulators, air separation tables, and dust collection systems. These systems are essential for cable recycling, e-waste processing, automotive shredder residue (ASR) cleanup, and composite material recovery. By removing metal contaminants early in the process, ERS Magnetic Separation reduces wear on cutting components, prevents equipment damage, and improves the quality of downstream separation.

Each magnetic separator is built for continuous operation with minimal maintenance. Reinforced housings, sealed bearings, and adjustable magnetic fields ensure long-term durability and precise control. The systems are soundproofed and compliant with CE safety standards, supporting clean, quiet operation in demanding industrial environments.

ERS engineers work closely with clients to design magnetic separation layouts that match facility constraints and production goals. Whether you're upgrading an existing line or building a new system, ERS provides turnkey integration, performance tuning, and operator training to ensure maximum ROI.

The advantages of ERS Magnetic Separation include precise metal extraction, improved equipment protection, optimized workflow, and low maintenance requirements. These features make ERS systems essential for any facility seeking to improve recyclability, reduce downtime, and increase the value of recovered materials.

By investing in ERS Magnetic Separation, manufacturers gain a powerful solution for metal recovery and system protection. These machines are built to transform contaminated scrap into clean, valuable feedstock—supporting sustainable operations and profitable recovery.

Eddy Current Separator

Used primarily with non-ferrous aluminum metals, our eddy-current separators are proven to cut aluminum loss and labor costs associated with sorters

Drum Magnet

Designed to efficiently and cost effectively remove large and small pieces of ferrous materials from material processing lines.

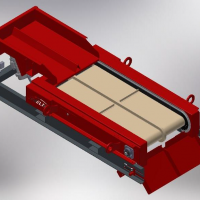

Cross Belt Magnet

Designed to pull ferrous and tramp metals from your recycling lines and any other conveyor configurations where metals need to be extracted

High Gauss Magnet

Our overhead self-cleaning, stationary and permanent high-gauss magnets are designed to pull ferrous and tramp metals from your recycling lines and any other conveyor configurations where metals need to be extracted.

Head Pulley Magnet

Available in numerous sizes, widths, diameters and magnet types, our head-pulley magnets can be designed to fit your specific application requirements.