OMER Tritone Shredders Series

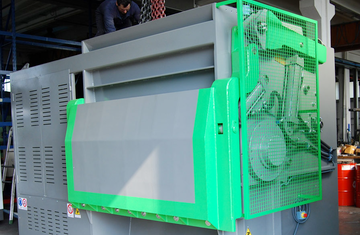

Tritone industrial shredders from Engineered Recycling Systems (ERS) are precision-engineered single-shaft machines designed for the aggressive reduction of tires, electrical cables, aluminum scrap, and bulky industrial waste. Manufactured by OMER and integrated by ERS, these shredders combine European craftsmanship with American systems expertise to deliver high-performance scrap processing across metals recycling environments.

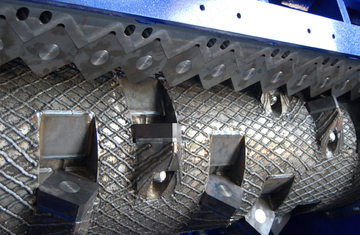

Each Tritone shredder features a solid rotor with a diameter of 460 mm and blade widths of 80 or 120 mm, depending on the model. The shaft is housed in a rib-reinforced frame that maintains alignment under heavy loads, while the cutter stack is engineered for consistent fragmentation and minimal wear. Available in rotor lengths of 1,100 mm, 1,500 mm, 1,800 mm, and 2,400 mm, Tritone shredders are scalable for small facilities and large industrial operations alike.

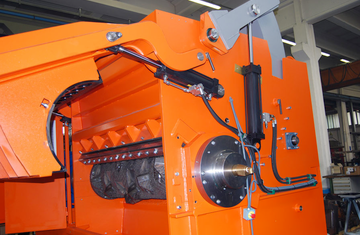

The shredding process begins with material intake through a wide-mouth hopper, followed by controlled fragmentation using hardened blades mounted on the rotor. A hydraulic pusher ensures continuous feed pressure, increasing hourly throughput and maintaining consistent particle sizing. The integrated screen grid allows operators to control output dimensions, optimizing the feedstock for downstream separation or refining.

Tritone industrial shredders are available with electric or hydraulic transmission, offering flexibility for facilities with specific power or torque requirements. Electric models range from 110 kW to 250 kW, while hydraulic variants provide enhanced torque for dense or composite materials. This adaptability makes Tritone ideal for processing tires, copper cables, aluminum profiles, electric motors, and mixed industrial scrap.

Maintenance access is streamlined through a front hatchback and blade control panel, allowing operators to inspect, clean, and service the shredder with minimal downtime. The design emphasizes durability and ease of use, with reinforced housings and CNC-machined components that ensure long-term alignment and structural integrity.

ERS integrates Tritone shredders into complete scrap processing lines, pairing them with conveyors, mills, separators, and dust collection systems. Whether you're handling ASR, e-waste, or bulky metal loads, Tritone units serve as the primary reduction stage, preparing material for final sizing and commodity recovery. Their performance supports high recovery rates, reduced labor costs, and compliance with environmental standards.

Each installation begins with a detailed assessment of material types, volume, and facility layout. ERS engineers configure the shredder and supporting systems to match operational goals, ensuring seamless integration and maximum ROI. Tritone shredders are trusted across the recycling industry for their reliability, throughput, and ability to handle diverse scrap streams.

By investing in Tritone industrial shredders from ERS, manufacturers gain a robust solution for metals recycling, waste reduction, and sustainable operations. These machines are built to transform difficult scrap into valuable feedstock, supporting cleaner workflows and profitable recovery.

Technical Data TRITONE Shredders

| Rotor Length |

Number of Shafts |

Rotor Ø |

Blades | Engine Power |

Power Source |

|---|---|---|---|---|---|

| 2,400 mm 94.48" |

1 | 460 mm 18.11" |

80/120 mm 3.14" / 4.72" |

250 kW 335.25 HP |

Electric |

| 1,100 mm 43.30" |

1 | 460 mm 18.11" |

80/120 mm 3.14" / 4.72" |

110 kW 147.5 HP |

Electric |

| 1,500 mm 59.05" |

1 | 460 mm 18.11" |

80/120 mm 3.14" / 4.72" |

132 kW 177 HP |

Electric |

| 1,800 mm 70.86" |

1 | 460 mm 18.11" |

80/120 mm 3.14" / 4.72" |

160 kW 214.56 HP |

Electric |

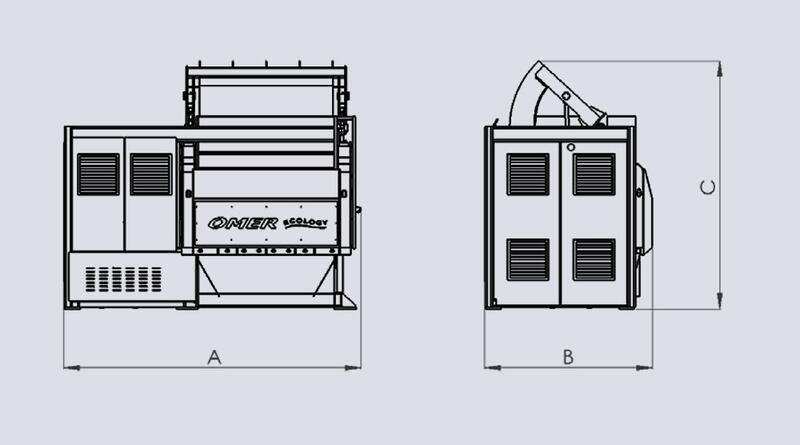

| Type | A | B | C |

|---|---|---|---|

| 2,400 | 5,325 mm 209.64" |

2,290 mm 90.16" |

3,540 mm 139.37" |

| 1,100 | 3,400 mm 133.85" |

2,290 mm 90.16" |

3,000 mm 118.11" |

| 1,500 | 3,895 mm 153.34" |

2,290 mm 90.16" |

3,200 mm 125.95" |

| 1,800 | 4,057 mm 159.72" |

2,290 mm 90.16" |

3,386 mm 133.30" |