Guidetti Dry Separation Tables

Guidetti Dry Separation Tables from Engineered Recycling Systems (ERS) are CE-certified systems designed to separate granulated materials of similar size but different density. These tables are ideal for recovering metals, plastics, wood, and other materials from mixed industrial scrap, delivering high-purity output with minimal energy consumption and maintenance.

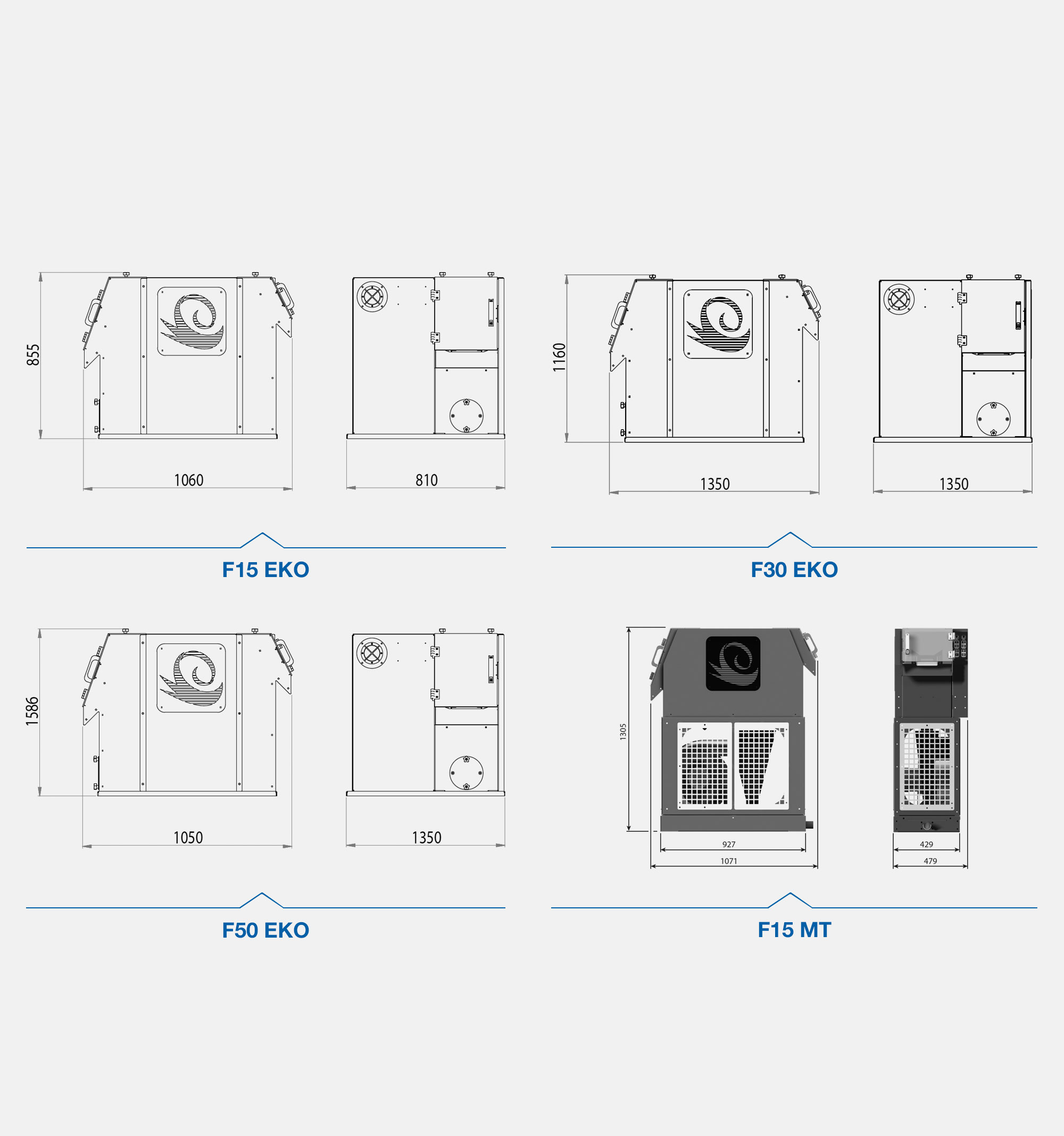

The ROBI Series includes multiple models tailored to different throughput and material types. The Robi 71 offers a compact footprint of 1930 × 1455 × 2030 mm, weighs 830 kg, and operates at 3.5 kW. The Robi 151 expands capacity with dimensions of 2170 × 1860 × 2395 mm, a weight of 1070 kg, and 5 kW installed power. ERS also integrates the F-Series tables—F15 Eko, F30 Eko, F50 Eko, and F15 MT—each designed for specific material streams and facility layouts. The F15 MT, for example, weighs just 115 kg and is ideal for small-scale or precision separation tasks.

ERS configures these tables to support continuous operation and inline integration with cable granulators, pre-shredders, and air separation systems. The dry separation process uses vibratory motion and airflow to separate materials based on specific gravity, without water or chemical treatment. This makes the system ideal for separating copper from aluminum, metals from PVC or rubber, plastics from sand or stones, and wood from glass or metal fragments.

Each table includes adjustable settings for airflow, vibration, and feed rate, allowing operators to fine-tune separation performance in real time. The systems are soundproofed and built with sealed bearings and reinforced housings to ensure long-term durability and compliance with CE safety standards.

ERS installs Guidetti Dry Separation Tables in cable recycling lines, plastic recovery systems, and wood processing facilities. Whether you're handling telecom cables, automotive harnesses, composite scrap, or mixed granules, these tables deliver consistent performance and high recovery rates. Their compact design and low energy consumption per ton of processed material make them a cost-effective choice for manufacturers, recyclers, and scrap processors.

The advantages of the ROBI Series include zero water usage, reduced acoustic pollution, lower energy consumption per ton of separated material, and rapid maintenance access. These features make the Guidetti Dry Separation Tables one of the most advanced and operator-friendly density separation systems available.

By investing in the Guidetti Dry Separation Tables from ERS, manufacturers gain a powerful, space-saving solution for density-based material recovery. These machines are built to transform mixed scrap into clean, valuable feedstock—supporting sustainable operations and profitable recovery.

| Technical Data |

Length | Width | Height | Weight | Power | Production |

|---|---|---|---|---|---|---|

| F15 MT |

1071 mm 42.2'' |

479 mm 18.9'' |

1305 mm 51.4'' |

115 kg 254 lb |

(*) changeable according to the material processed kg/h |

|

| Robi 71 | 1930 mm 57.3'' |

1455 mm 57.2'' |

2030 mm 79.9'' |

830 kg 1830 lb |

3.5 kw 4.7 HP |

(*) changeable according to the material processed kg/h |

| Robi 151 | 2170 mm mm 85.4'' |

1860 mm 73.2'' |

2395 mm 94.3'' |

1070 kg 2359 lb |

5.0 kw 6.7 HP |

(*) changeable according to the material processed kg/h |

| F15 Eko |

1060 mm 41.7'' |

810 mm 31.9'' |

855 mm 33.7'' |

192 kg 423 lb |

0.76 kw 1.0 HP |

(*) changeable according to the material processed kg/h |

| F30 Eko |

1350 mm 53.1'' |

1350 mm 53.1'' |

1160 mm 45.7'' |

535 kg 1179 lb |

1.8 kw 2.4 HP |

(*) changeable according to the material processed kg/h |

| F50 Eko |

1050 mm 41.3'' |

1350 mm 53.1'' |

1586 mm 62.4'' |

390 kg 860 lb |

2.0 kw 2.7 HP |

(*) changeable according to the material processed kg/h |