Pre-Shredder

Guidetti

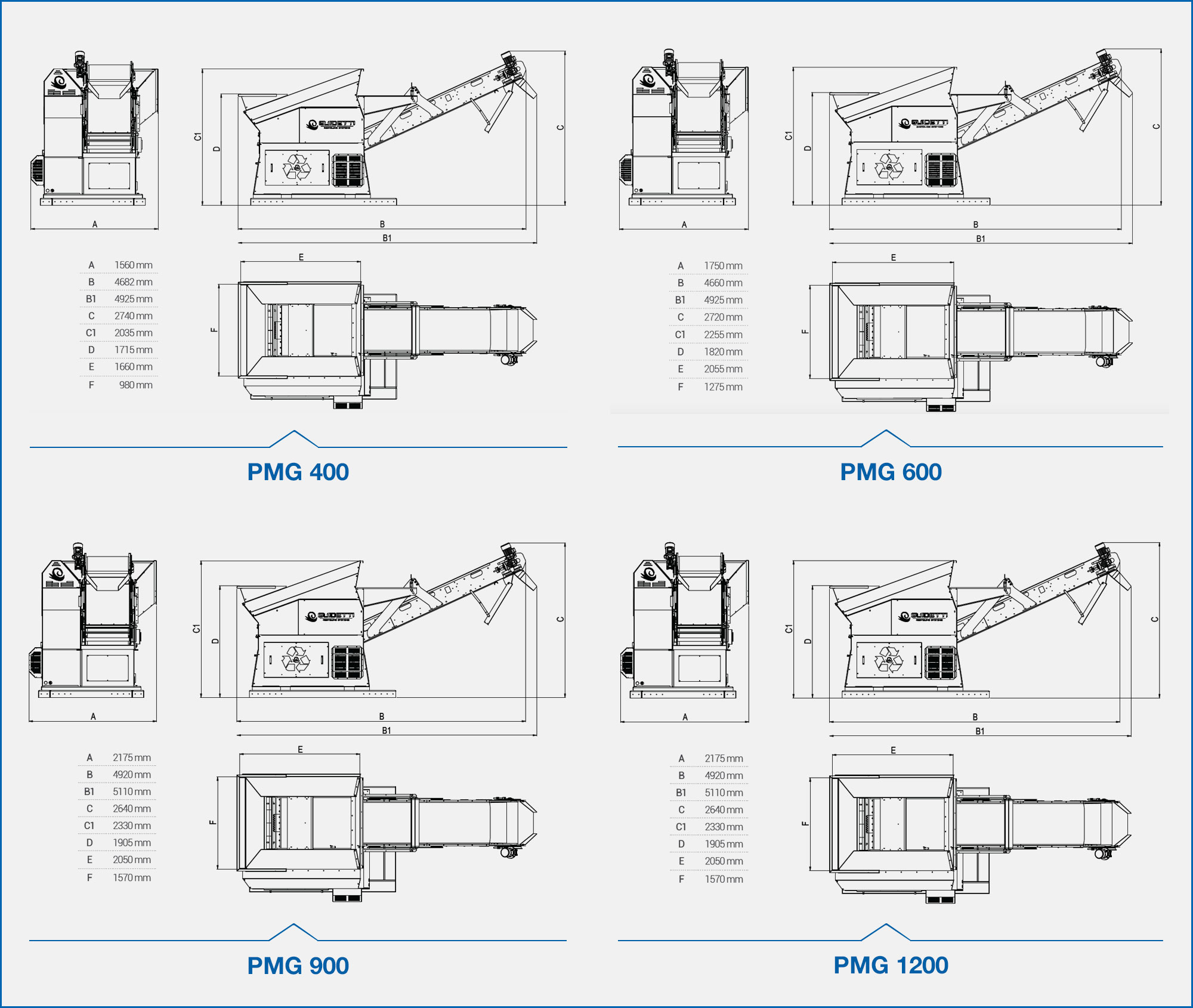

PMG 400

Guidetti PMG Pre-Shredders Series

PMG pre-shredders from Engineered Recycling Systems (ERS) are engineered for primary reduction of metals, tires, and bulky industrial waste. These machines initiate the scrap processing workflow with high-torque, low-speed fragmentation that prepares material for downstream shredding, grinding, or separation.

The PMG series is designed to handle oversized and irregular scrap streams with aggressive intake and controlled fragmentation. Each unit features dual shafts rotating independently to pull material inward and break it down through intermeshing cutter stacks. This low-speed approach minimizes dust, reduces noise, and delivers consistent particle sizing without the need for screens or secondary grinding.

ERS PMG pre-shredders are built with rib-reinforced housings and CNC-machined components to maintain shaft alignment and gearbox stability under extreme loads. The cutter stacks are configured for maximum contact and efficient fragmentation, making these machines ideal for tires, aluminum profiles, steel drums, and mixed industrial waste. Multiple rotor lengths and cutter arrangements are available to match specific material types and throughput goals.

Hydraulic drive options provide enhanced torque and overload protection, allowing for variable speed control and automatic reversal during peak loads. Gearbox-driven models offer consistent performance for predictable scrap streams, with reduced energy consumption and simplified maintenance. ERS engineers configure each system to match facility layout, material flow, and operational requirements.

Maintenance access is streamlined through hinged covers and service panels, allowing operators to inspect and clean the shredder without extended downtime. Shaft couplings and bearing assemblies are designed for longevity, with protective seals that resist contamination and wear. These features ensure smooth operation, reduced wear, and minimal downtime in high-volume industrial settings.

ERS integrates PMG pre-shredders into complete processing lines, pairing them with conveyors, hammer mills, separators, and dust collection systems. Whether you're handling automotive scrap, e-waste, or bulky packaging waste, these machines serve as the first stage of reduction, preparing material for final sizing and commodity recovery. Their performance supports high recovery rates, reduced labor costs, and compliance with environmental standards.

Each installation begins with a detailed assessment of material types, volume, and facility layout. ERS engineers design the shredder and supporting systems to match operational goals, ensuring seamless integration and maximum ROI. PMG pre-shredders are trusted across the recycling industry for their reliability, throughput, and ability to handle diverse scrap streams.

By investing in PMG pre-shredders from ERS, manufacturers gain a robust solution for metals recycling, waste reduction, and sustainable operations. These machines are built to support cleaner workflows, profitable recovery, and long-term performance in demanding industrial environments.

| Technical Data |

Length | Width | Height | Weight | Power | Production |

|---|---|---|---|---|---|---|

| PMG 1200 | 3,560 mm 140.2" |

2,300 mm 90.6" |

2,540 mm 100.0" |

4,450 kg 10,031 lb |

78.0 kW 104.6 HP |

kg/h |

| PMG 400 | 1,560 mm 61.4" |

4,682 mm 184.3" |

2,740 mm 107.9" |

1,420 kg 3,131 lb |

12.5 kW 16.8 HP |

kg/h |

| PMG 600 | 1,750 mm 68.8" |

4,660 mm 183.5" |

2,720 mm 107.1" |

1,840 kg 4,057 lb |

20.0 kW 26.8 HP |

kg/h |

| PMG 900 | 2,175 mm 85.6" |

4,920 mm 193.7" |

2,640 mm 103.9" |

2,100 kg 4,630 lb |

32.0 kW 42.9 HP |

kg/h |